How Heat Transfer Fluid Influences the Effectiveness of A/c Systems

How Heat Transfer Fluid Influences the Effectiveness of A/c Systems

Blog Article

The Duty of Warm Transfer Fluid in Enhancing System Performance and Safety

In the ever-evolving landscape of commercial procedures, warm transfer liquids (HTFs) emerge as pivotal components in optimizing both system efficiency and safety and security. These specialized fluids, understood for their premium thermal conductivity and regulated thickness, make it possible for reliable warmth exchange, which is indispensable for structured procedures. Nevertheless, the influence of HTFs prolongs beyond plain effectiveness; their intrinsic thermal security and reduced flammability substantially add to take the chance of reduction. As industries come to grips with the requirement for high-performance and risk-free operations, understanding the nuanced duty of HTFs ends up being important. What specifically makes HTFs so essential in today's industrial frameworks?

Comprehending Warm Transfer Fluids

Warmth transfer fluids, commonly considered the lifeline of thermal administration systems, play an essential role in regulating temperature level throughout different commercial applications - heat transfer fluid. Industries such as chemical handling, power generation, and production count on warm transfer liquids to guarantee tools operates effectively and securely.

The selection of an ideal heat transfer fluid is crucial to the success of a thermal management system. Comprehending the nature and function of these liquids entails acknowledging their ability to take in, transport, and release heat efficiently. Heat transfer fluids can be generally classified right into various types, including water-based, glycol-based, and artificial oils, each with its details applications and advantages. The option of fluid depends upon factors such as temperature level array, thermal security, and compatibility with system materials. In summary, a thorough understanding of warm transfer liquids is crucial for maximizing system performance, guaranteeing functional security, and achieving economical thermal monitoring remedies.

Key Characteristic of HTFs

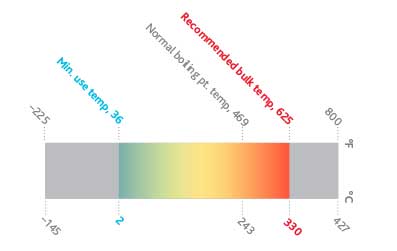

The details heat capability of an HTF defines the amount of heat required to change its temperature, influencing just how efficiently the system can reply to temperature variants. The boiling and freezing factors of HTFs additionally play a crucial duty, specifically in systems exposed to severe temperatures, ensuring liquid stability and preventing phase modifications throughout operation. Furthermore, the chemical stability of HTFs under differing thermal problems is important to stop deterioration and extend fluid life. Finally, compatibility with system products is needed to avoid deterioration and product destruction, ensuring long-lasting functional integrity. These homes jointly notify the choice of an appropriate HTF for certain industrial applications.

Enhancing System Efficiency

To boost system efficiency with heat transfer fluids (HTFs), it is necessary to incorporate a detailed technique that thinks about both liquid homes and system design. The choice of an ideal HTF is pivotal, as its thermal conductivity, thickness, and certain warmth capacity straight influence the effectiveness of warmth exchange. High thermal conductivity guarantees rapid heat transfer, while optimum viscosity facilitates smooth flow via the system, reducing energy usage. Furthermore, a high details heat capacity allows the liquid to store and move even more thermal power, enhancing overall system efficiency.

Similarly essential is the design of the warmth transfer system itself. Designers have to ensure that components such as heat exchangers, pumps, and description piping are designed to match the buildings of the picked HTF. For example, the surface and product of warmth exchangers must be optimized to maximize heat transfer efficiency. Furthermore, the assimilation of sophisticated modern technologies, such as variable speed pumps and clever surveillance systems, can dramatically enhance the responsiveness and versatility of the system to altering functional problems.

Boosting Operational Safety And Security

Guaranteeing operational safety and security in warm transfer systems calls for a precise emphasis on both the buildings of warmth transfer fluids (HTFs) and the design and upkeep of the whole system. HTFs should have thermal stability, reduced flammability, and appropriate thickness to reduce threats such as leaks, fires, and system malfunctions. continue reading this Choosing the best HTF is critical as it figures out the system's capability to manage temperature level fluctuations without compromising safety.

The layout of the system ought to include redundancies and fail-safes to take care of possible risks successfully. This includes the integration of safety and security shutoffs, stress alleviation tools, and temperature level tracking systems to identify and deal with abnormalities without delay. Regular upkeep is important to make certain that all components, including pumps, pipelines, and seals, are working appropriately and are without wear or rust, which might lead to harmful leaks or failures.

Furthermore, employees liable for the operation and maintenance of warmth transfer systems have to be adequately educated in security methods and emergency action treatments. Regular training programs and security drills can dramatically lower the probability of mishaps, making sure a more secure working environment. Eventually, a comprehensive strategy to security-- including liquid option, system design, and workforce training-- is important for ideal functional security.

Sector Applications of HTFs

Commonly utilized across various markets, warmth transfer liquids (HTFs) play a crucial duty in improving the efficiency and reliability of thermal management systems. In the chemical market, HTFs are essential for preserving accurate temperatures throughout responses, making certain item uniformity and top quality. They promote heat exchange processes in activators, condensers, and heat exchangers, therefore optimizing power use and minimizing waste.

In the oil and gas industry, HTFs are utilized in both upstream and downstream operations. They manage temperature in drilling operations and improve efficiency in refining processes by supplying secure thermal more tips here problems. This causes reduced downtime and improved safety and security, especially in essential operations such as purification and splitting.

The renewable resource market also profits significantly from HTFs, particularly in focused solar power (CSP) plants. Here, HTFs move recorded solar energy to power wind turbines, enabling efficient electricity generation. The pharmaceutical industry depends on HTFs for exact temperature control in both synthesis and storage, making sure product efficiency and safety and security.

Furthermore, the food and drink field uses HTFs for pasteurization, sanitation, and food preparation procedures, boosting both product safety and manufacturing effectiveness. Throughout these industries, HTFs act as essential elements in preserving optimum functional performance and security.

Verdict

Warmth transfer fluids are crucial in boosting commercial system performance and security by supplying high thermal conductivity, ideal viscosity, and thermal security. Correct choice and maintenance of HTFs enhance warmth exchange effectiveness, thus enhancing operational performance. The reduced flammability of these liquids is important for reducing risks and making certain secure operations. Comprehensive employees training and routine maintenance further sustain the integrity and performance of commercial processes, strengthening the critical function of HTFs in varied applications.

Report this page